G Z2

|

|

|

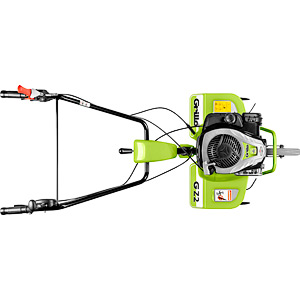

The GZ2 is a compact tiller, ideal for tilling easily even where there is not much space. |

|

|

The Grillo GZ2 is equipped with active coupling device; in fact, the lever on the handlebar, when pressed, starts the rotation of the tines. When the lever is released the tines stop immediately but the engine remains running. |

|

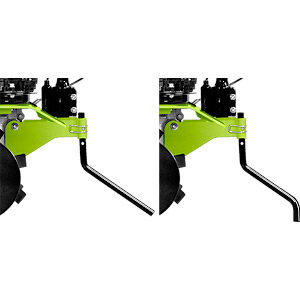

Two spurs are supplied as standard: one for soft soil and one for hard soil. The adjustment of the spur determines the working depth. |

|

|

The 3 HP motor provides adequate torque for tilling already at 2400 rpm! You can till slowly, from 80-90 rpm, or quickly, up to 155 rpm, depending on soil conditions and the desired level of soil shredding. Even for the deepest tillage, with the tiller at full width and totally buried, engine power places no limitations on the GZ2! |

|

The height-adjustable handlebar will meet the needs of all users, and the right position will always be found for all working depths. |

|

|

Cleaning and maintenance are super easy! Simply check the engine oil level periodically and clean the filter. The gearbox does not require any maintenance. The GZ2, like all Grillo products, is designed and built to last and maintain its value over time. All components, from the simplest to the most complex, are of high quality. Grillo mounts the latest generation engine equipped with a Ready Start device for easy starting! All engines feature overhead valves to have minimal fuel consumption, emissions, noise and vibration. Frame, handlebar, tiller, everything is built by Grillo in Italy, using the best materials and the latest technology to have high, consistent and 100% controlled quality. |

|

The tempered steel tines can be detached and easily replaced! Painting of all Grillo machines is made with a double electrostatic powder coating process. After washing and preparation, a first protective coat is applied then baked in a special oven; this has proven to be the best base for the application of the finish. The second coat consists of powder coating and further baking in an oven at 190°C; this gives the characteristic hardness and shine. All machines are assembled with care in every detail and tested scrupulously by trained personnel. Final inspection includes running the engine in order to check all its functions to guarantee a first class product. |

|

| All Grillo machines are distributed and serviced by a widespread dealer network. Spare parts remain available for many years after production has stopped, giving you extra confidence in Grillo. |

|

Engine |

Briggs & Stratton 575EX OHV Start recoil starter Supply fuel Displacement 140 cc, 1 Cylinder Power 3 HP (2.2 kW) Air cooled Dry air filter |

|

Fuel tank capacity | 0,8 L |

|

Transmission | endless screw in oil bath |

| Gearbox | 1 forward gear + 1 reverse gear | |

| Clutch | active coupling | |

|

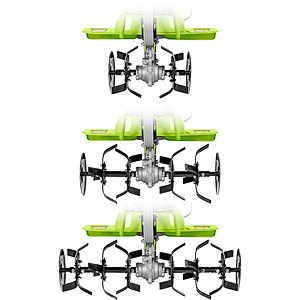

Standard rotary tiller | with 4 tines and side discs, working width 52 cm |

| Hoes system diametre | 28 cm | |

| Working width area with side disks | 57 cm. With the optional kit, the tiller can be adjusted at 35 and 80 cm. | |

| Working depth area without side disks | 52 cm. With the optional kit, the tiller can be adjusted at 30 and 75 cm. | |

| Working depth | 28 cm | |

| Max. revolutions tiller | 155 rpm | |

| Handlebar | height and side - adjustable | |

| Standard features | Front transport wheel. Two different spurs, one for hard soils, one for soft and sandy soils. | |

| Safety devices | Active coupling: If the handlebar is released the machine stops; mudguards and handlebars compliant with the current laws and muffler protection. | |

|

Weight | 41 kg |

Full Range Catalogue 2024

(Download - file pdf - 21,78 MB)

Full Range Catalogue 2024

(Download - file pdf - 21,78 MB)

Motorhoes leaflet - 2022

(Download - file pdf - 2,95 MB)

Motorhoes leaflet - 2022

(Download - file pdf - 2,95 MB)